What is ISA 88?

ISA 88 (also known more simply as “S88”) is a set of standards for implementation of Batch Control systems. Its purpose is to provide consistent terminology and a framework for designing and modularising batch control systems.

The S88 standard details three models for defining a batch control system:

- Physical model – defines the physical equipment configuration

- Procedural model – defines the generic instructions that are used for batch control

- Process model – defines the processing actions for each unit

Physical Model

This is a way of dividing the physical equipment into a hierarchical structure as shown in the following diagram:

Process Cell

This represents the entire plant under consideration and contains all the equipment required to make a batch. Process cells consist of one or more units.

Unit

A unit is made up of equipment modules and control modules. A unit is an independent grouping of equipment usually centred around a major piece of processing equipment, such as a mixing tank or reactor.

Characteristics of a unit:

- A unit can execute one or more major processing activities, such as react, crystallize, and make a solution.

- Units operate relatively independently of one another.

- A unit often contains a complete batch of material at some point in the processing sequence of the batch.

- A unit cannot process more than one batch at the same time.

Equipment Module

An equipment module can be made up of control modules and subordinate equipment modules. An equipment module is usually centred on a piece of processing equipment, such as a filter.

Characteristics of an equipment module:

- Can be part of a unit or stand-alone grouping of equipment within a process cell.

- Can carry out a finite number of specific minor processing activities, such as dosing or weighing.

- Can, but does not need to contain the raw materials for a batch

Control Module

A control module is usually a collection of sensors, actuators, other control modules and associated processing equipment that can be operated as a single entity from the point of view of control engineering. These can also be thought of as “devices” or “loops”. A control module can also be made up of other control modules.

Examples of control modules: isolation valves, modulating valves, analog transmitters, PID controllers, motors

Procedural Model

This is a way of defining the procedure used to make a product as shown in the following diagram:

The entire procedure for making a product is called a Recipe Procedure, which itself is divided into Unit Procedures. Unit Procedures consist of major processing steps called Operations. Operations consist of small individual processing steps called phases.

Unit Procedures generally correspond to the Units from the Physical Model.

Phases usually correspond to individual calls of Equipment Modules from the physical model. In each call, certain parameters are passed to the Equipment Module which instruct it how to operate.

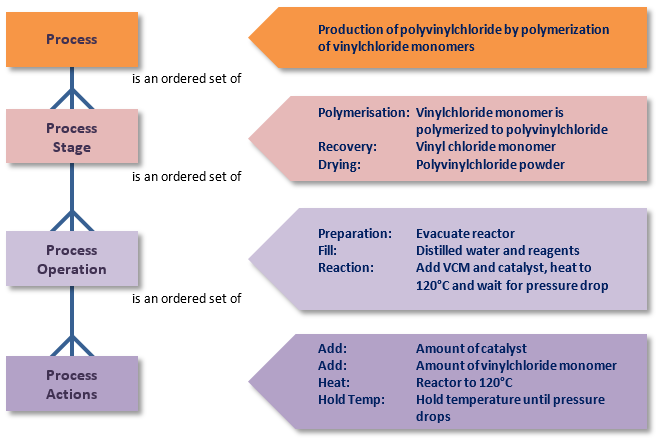

Process Model

The Process Model consists of a process which consists of an ordered set of process stages, which consist of an ordered set of process operations, which consist of an ordered set of process actions.

Implementation of S88 in Control Systems

In batch control systems the software is usually structured according to the physical model. Thus devices like valves, motors, PID controllers will become control modules. These will in turn be controlled by equipment modules, which in turn belong to units (although some equipment modules could be stand-alone). Usually this will be achieved by structuring the software into a hierarchical folder structure.

In terms of writing functional requirements and design specifications, those documents would be structured using the same idea: Divide the physical plant into units, equipment modules and control modules. The equipment modules would be further divided into phases which each have parameters that determine their behaviour.

The procedural control is usually done by creating recipes in a recipe editing software package. Recipes would consist of unit procedures that call on the underlying equipment modules. Each call to an equipment module would specify parameter values that get passed to the equipment module.

Relevant Industries

ISA 88 is intended for batch processing industries. It is used particularly in industries with higher regulatory requirements like pharmaceutical manufacturing and food and beverage manufacturing, however it is relevant for any batch processing environment.

Mescada Experience with ISA 88

Mescada have extensive experience implementing S88-compliant batch systems, particularly in the pharmaceuticals industry and the food and beverage industry. In fact, these industries are Mescada’s biggest clients.

Mescada can provide the following services:

- Initial project scoping and planning

- Specification of control system hardware and software licences

- Development of functional requirements specifications and design specifications

- Programming and development of the control system software

- Testing of the system, including FAT and SAT

- Support for commissioning and start-up